In Design by admin

Changing conveyor idler rollers is a time consuming, risky and inefficient task. The current method used to change idler rollers involves stopping production, isolating equipment, lifting the conveyor belt and manhandling the idler rollers to and from the conveyor installation (idler rollers can weigh up to 65kg each). There are a significant number of injuries caused each year from this task. In an average bulk handling facility, a single idler roller replacement causes over one hour in downtime, resulting in significant production losses.

The Spidler® was developed by Sandpit Innovation and Lewis Australia in response to the safety and financial risk’s involved in manually changing conveyor idler rollers. The Spidler® is able to provide:

- Safety – Significant health and safety improvements by limiting the need to manually change idler rollers by utilising game-changing robotic technology.

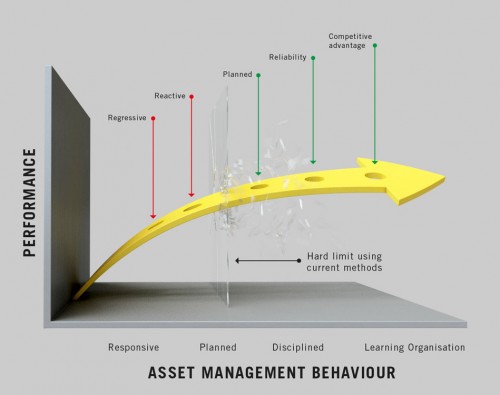

- Asset management – Provides a complete asset management solution to revolutionise the way rollers are managed and significantly reduce the excessive cost of current idler replacement strategies.

- Prevention – Onboard condition monitoring to detect and change an idler roller before a problem arises.

- Reduced downtime – Reduced downtime caused by failed idler rollers.

- 24/7 – Allows idlers to be replaced any time of the day while the conveyor operates, negating the need to plan major roller changes during shutdowns.

- Fully tested - A working prototype has been developed and fully tested on a live iron ore out-load conveyor.

A working prototype has been developed and tested on an operating iron ore out-load conveyor in Port Hedland.