Considerable time and effort was spent on understanding the current people and process elements used to manage and replace conveyor idler rollers.

Our Design Approach

Sandpit Innovation, the developer of the Spidler®, is passionate about identifying and implementing fit-for-purpose solutions for tricky problems. From our operational experience we know that “silver bullets” do not yield results and that people, process and technology are required to create something that will work and will deliver results.

We analysed the potential operational value in changing different aspects of the process and the commonalities between designs. This allowed us to design a machine that was truly fit-for-purpose and which addressed the core problems with manual interaction and having to stop a conveyor to replace an idler roller - planned or unplanned.

The Spidler® has a clear path towards further automation and supports changing the entire asset management process used to manage idler rollers. The design is not limited by surrounding terrain, weather conditions or conveyor angle, which were all highlighted as key limitations in potential designs.

CONCEPT PROVEN

In order to prove the concept and reduce the development risk, a proof-of-concept (PoC) machine able to change idler rollers while the conveyor continued to operate, was designed and built.

The PoC machine aimed to validate, in an operational environment, that it is possible to use robotics to change a live carrier idler roller, in addition to demonstrating that a fully loaded conveyor belt could be lifted to allow the robot to reach under the running conveyor to replace an idler roller.

The PoC Spidler® was successfully demonstrated at an operating site in Port Hedland on the 5th of June, 2013.

CHANGING IDLER ROLLER ASSET

MANAGEMENT

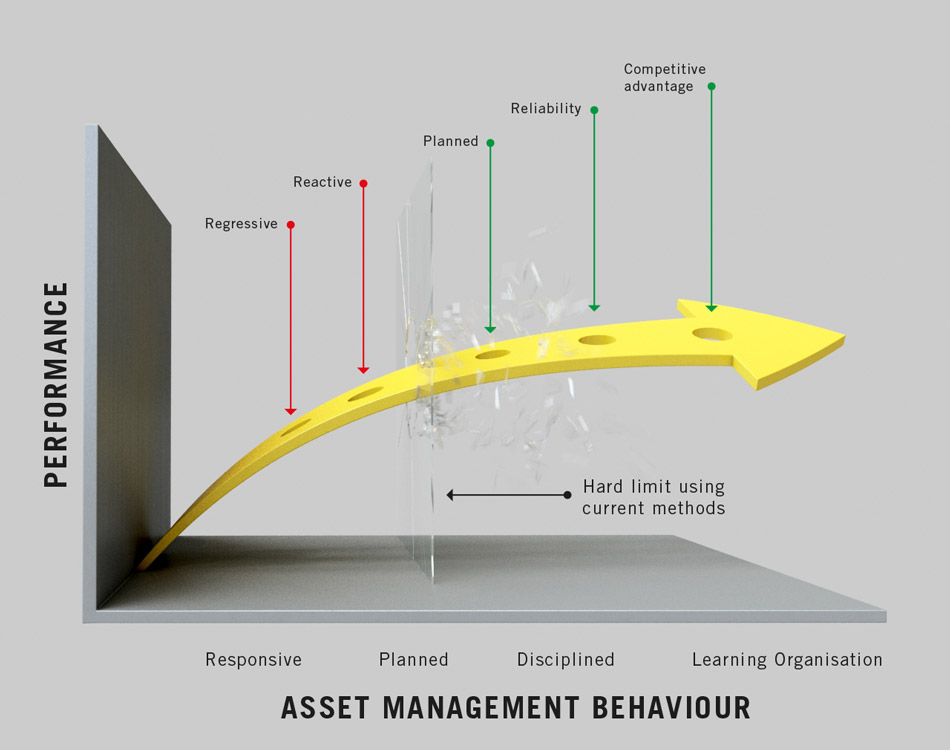

The Spidler® has been designed to not only eliminate production losses caused by idler roller failures, but provides a complete asset management solution to revolutionise the way idler rollers are managed, while eliminating human intervention.

The Spidler® enables work identification and the work management process to be fully optimised…

- The Spidler® can provide the means to detect rapid failures & random failures

- Since the machine is ‘on-line’, it supports a reliability based change-out strategy

- The Spidler® can support new operating philosophies which are currently not attainable