Changing conveyor idler rollers is a time consuming, risky and inefficient task. The current method used to change idler rollers involves stopping production, isolating equipment, lifting the conveyor belt and manhandling the idler rollers to and from the conveyor installation (idler rollers can weigh up to 65kg each).

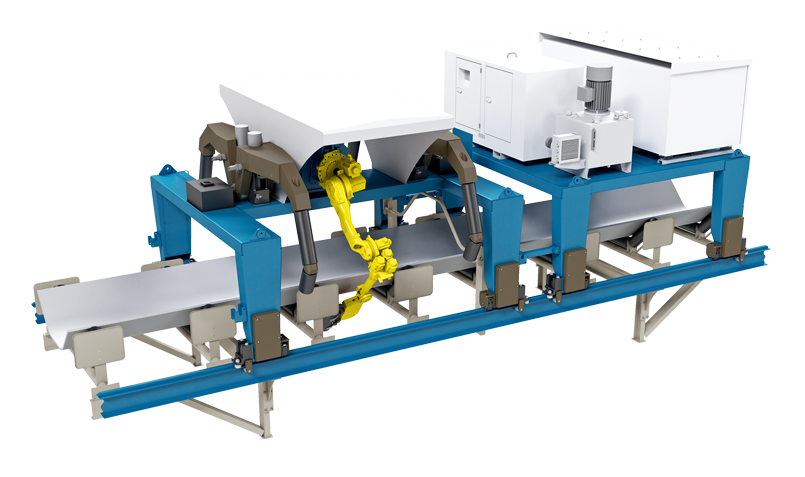

There are a significant number of injuries caused each year from this task. In an average bulk handling facility, a single idler roller replacement causes over one hour of downtime, resulting in significant production losses. The Spidler® was developed by Sandpit Innovation in response to the physical and financial risks involved in manually changing conveyor idler rollers.